Transdermal patches have become an essential tool in delivering medication and active ingredients directly through the skin. The methods used to produce these patches vary widely, each offering unique advantages. Let’s explore the key techniques, including the growing field of microneedling.

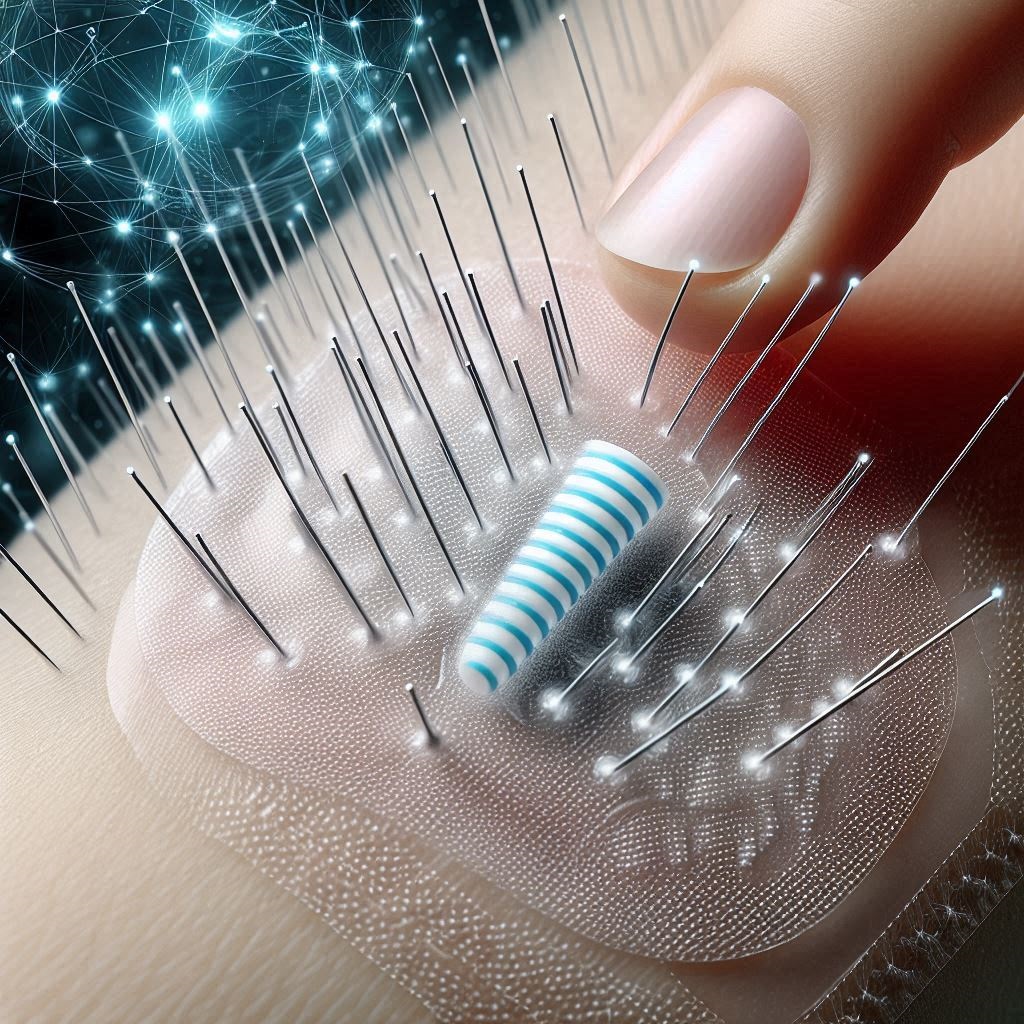

1. Microneedling

Microneedling is an advanced method that enhances transdermal drug delivery by using tiny, painless needles embedded within the patch. These microneedles create microchannels in the skin, allowing active ingredients to bypass the outermost barrier and be absorbed directly into deeper layers.

Advantages: Microneedling significantly increases the efficiency of drug delivery, especially for large molecules that struggle to penetrate the skin. It’s also minimally invasive, causing little to no discomfort while delivering therapeutic compounds more effectively.

Disadvantages: The production of microneedling patches is complex and requires specialized equipment. Additionally, while microneedles are generally safe, there may be a slight risk of skin irritation or infection if not used properly.

2. Solvent Casting Method

The solvent casting method involves dissolving the drug and other ingredients in a solvent, which is then spread onto a backing layer. The solvent evaporates, leaving behind a drug-loaded film. This method is widely used for its control over drug load and patch thickness.

Advantages: Precise drug loading and uniform film formation are key benefits of this method.

Disadvantages: The use of organic solvents can leave residues and pose environmental challenges.

3. Hot-Melt Extrusion

Hot-melt extrusion involves heating a drug-polymer mixture and extruding it into a continuous sheet, which is then cooled and cut into patches. This method is solvent-free and ideal for heat-stable drugs.

Advantages: Environmentally friendly with excellent drug stability.

Disadvantages: Not suitable for heat-sensitive drugs.

4. Drug-in-Adhesive System

In the drug-in-adhesive system, the drug is mixed directly into the adhesive that sticks the patch to the skin. This method ensures close contact between the drug and skin, enhancing absorption.

Advantages: Simplifies manufacturing by combining drug and adhesive in one layer.

Disadvantages: Limited drug load capacity and potential for uneven drug distribution.

5. Matrix System

The matrix system disperses the drug within a polymer matrix, forming the core of the patch. The drug is released at a controlled rate as it diffuses through the matrix and into the skin.

Advantages: Provides sustained and controlled drug release.

Disadvantages: Requires precise formulation to achieve desired release rates.

6. Reservoir System

The reservoir system contains the drug in a liquid or gel-filled compartment, separated from the skin by a semi-permeable membrane. The drug diffuses through the membrane for controlled, long-term delivery.

Advantages: Highly controlled and predictable drug release.

Disadvantages: More complex manufacturing process with potential leakage issues.

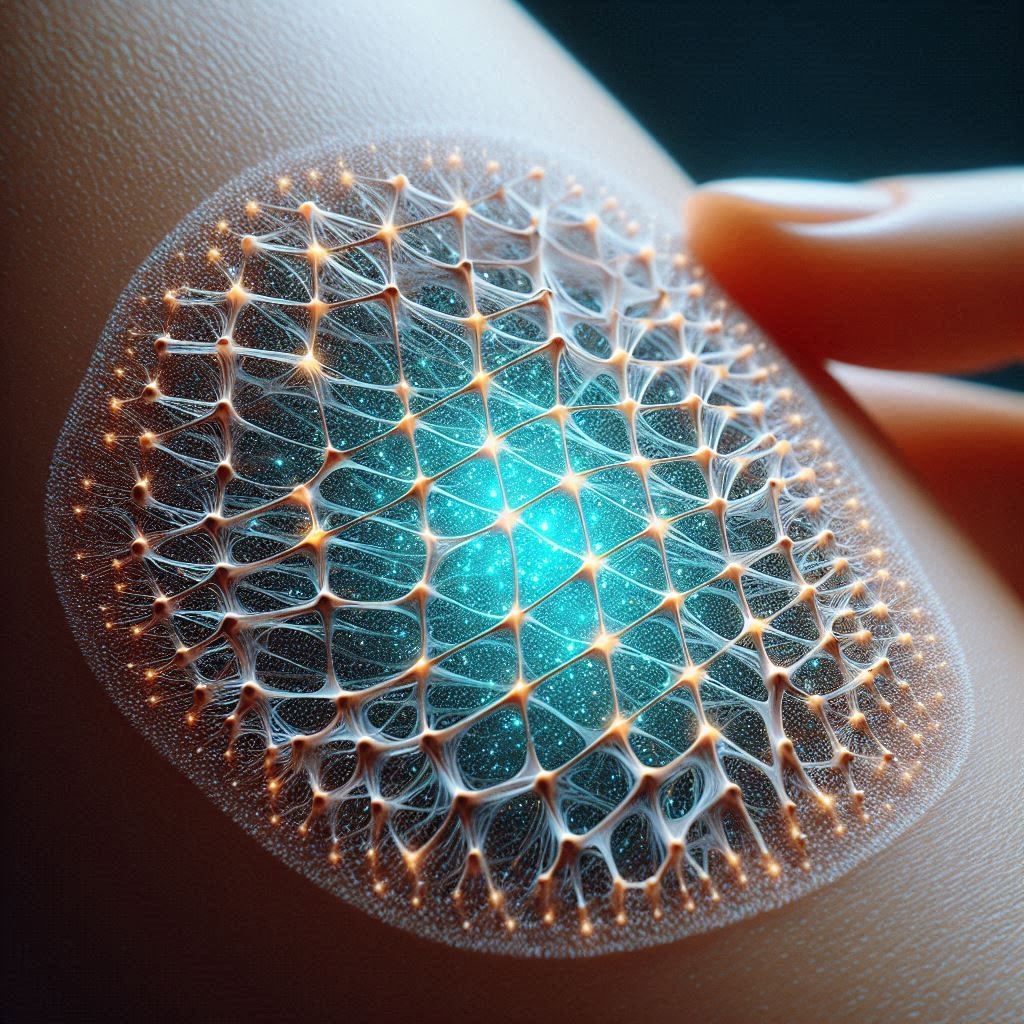

7. Electrospinning

Electrospinning creates nanofiber mats by applying high voltage to a polymer-drug solution. These mats offer a high surface area, enabling rapid drug absorption and targeted delivery.

Advantages: Produces ultrafine fibers with enhanced drug loading and release rates.

Disadvantages: Requires specialized equipment and expertise.

Conclusion

Each method of producing transdermal patches offers distinct advantages, from the precision of electrospinning to the simplicity of drug-in-adhesive systems. As technology advances, these methods continue to evolve, offering more efficient, comfortable, and effective solutions for transdermal drug delivery. Whether you need a patch for medication or skincare, understanding these production techniques can help you make informed decisions for better health outcomes.